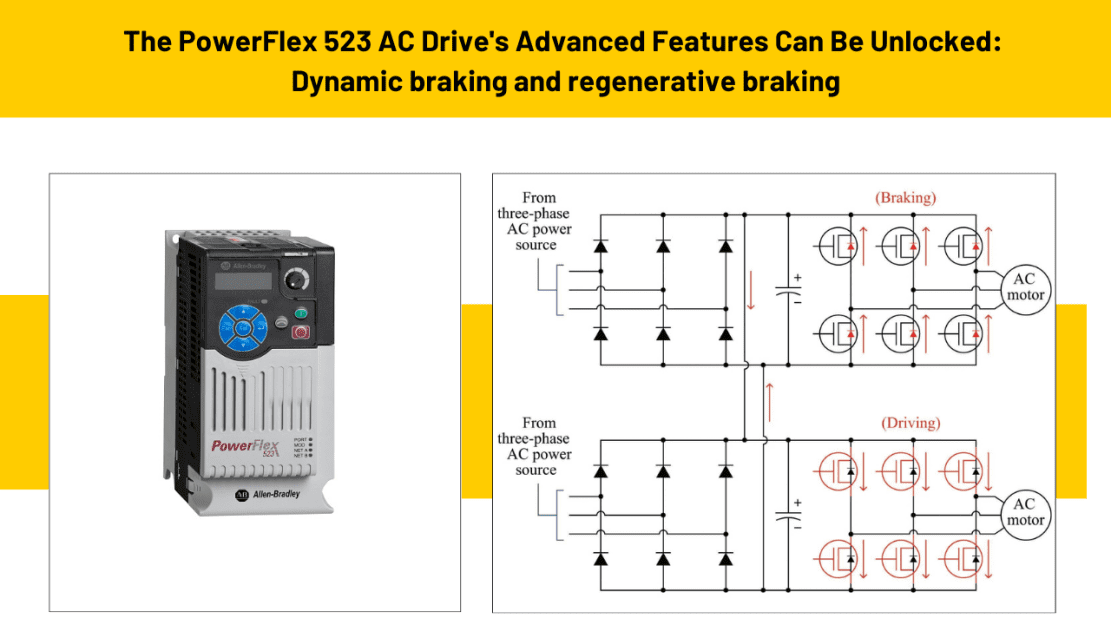

The PowerFlex 523 AC Drive’s Advanced Features Can Be Unlocked: Dynamic braking and regenerative braking

The PowerFlex 523 AC drive’s two cutting-edge features, dynamic braking and regenerative braking, enhance the performance and energy efficiency of motor-driven systems.

-

Regenerative Braking:

Regenerative braking is a feature of the Allen Bradley PowerFlex 523 AC drive that enables it to store and transfer energy created during a motor’s slowness or braking. Instead of releasing this energy as heat, the drive converts it into useful electrical power that may be used by other plant equipment or sent back into the power supply system.

Regenerative braking offers a number of benefits, including:

- Energy Savings: By capturing and reusing the energy that would otherwise be wasted, regenerative braking significantly improves the energy efficiency of motor-driven devices. This leads to lower running costs and energy consumption.

- Increased System Efficiency: Regenerative braking increases the overall efficiency of the motor-driven system by minimising energy losses. The recovered energy can be used to power more motors or devices, reducing the requirement for additional power sources.

- Heat Reduction: Instead than allowing excess energy escape as heat, regenerative braking converts it into useable electricity. By keeping them cooler, this lengthens the lifespan of the motor and other system parts and reduces the likelihood of overheating.

- Environmental Impact: By gathering and reusing energy, regenerative braking contributes to more environmentally friendly operations. This reduces the carbon footprint of the industrial site and promotes environmentally beneficial behaviours.

To use the regenerative braking feature, the PowerFlex 523 AC drive must be correctly setup and parameterized. The drive’s feedback and control loops may need to be set up, the brake resistors may need to be adjusted, and the braking torque control’s settings may need to be changed.

Also Read :- Rockwell Automation PowerFlex 523 AC Drive

-

Dynamic Braking:

Dynamic braking is a crucial feature provided by the PowerFlex 523 AC drive. It aids in the rapid and controlled deceleration of a motor by distributing extra energy as heat. This skill is useful when halting or decelerating has to happen swiftly and accurately.

The following are the primary characteristics and benefits of dynamic braking:

Precise Deceleration: Dynamic braking allows for fine control of a motor’s deceleration. It enables smooth and accurate stopping, which is essential in situations where precise positioning or controlled movement are essential.

Precise deceleration is the ability to accurately control and slow down the motor during the deceleration process. In order to provide precise positioning, controlled movement, and precise stopping at specified places, it ensures that the motor-driven system slows down or stops smoothly.

Dynamic braking, a feature of the PowerFlex 523 AC motor, allows for precise deceleration. This technique enables the drive to dissipate excess energy as heat, resulting in controlled deceleration and preventing sudden stops or jolts that might damage the system and its components.

- Load Protection: By protecting the motor and other system components from the possible impact of a rapid deceleration, dynamic braking helps. By distributing the surplus energy as heat, dynamic braking reduces the possibility of equipment damage and removes mechanical stress.

- Mechanical Stress Reduction: When the weight accelerates, stops suddenly, or changes directions, mechanical stress may be applied. The load safety mechanisms on the PowerFlex 523 AC drive assist lower this stress by ensuring controlled and smooth deceleration, preventing excessive force or strain on the load and its components.

- Avoiding Product Damage: In situations where the motor drives delicate or sensitive items, such as in packing or handling operations, load protection is crucial. Precise deceleration helps limit product damage caused by sudden stops or high impact forces, protecting the items’ integrity and quality.

- Equipment Longevity: By implementing load protection methods, the PowerFlex 523 AC drive helps to increase the lifespan of the motor-driven system and its components. Due to the controlled deceleration, the mechanical parts endure less wear and tear and require fewer repairs or replacements overall.

- Enhanced Safety: By offering regulated deceleration, dynamic braking improves the motor-driven system’s overall safety. Accidents, crashes, or damage to the equipment and workers are less likely to happen if you help avoid unforeseen movements, stops, or reversals.

- Heat Dissipation: During dynamic braking, the additional energy produced during deceleration is dissipated as heat. By limiting the buildup of excessive heat, this helps to increase the durability and reliability of the motor and other components.

To employ dynamic braking, the PowerFlex 523 AC drive must be configured and parameterized. Setting the appropriate brake settings, such as the deceleration rate and braking torque control, is necessary to produce the optimal deceleration characteristics.

By implementing dynamic braking in the PowerFlex 523 AC drive, manufacturers can assure precise and controlled deceleration, protect their equipment, enhance safety, and overall raise the efficiency and reliability of their motor-driven applications.

Access to these sophisticated features requires correct configuration and parameterization of the PowerFlex 523 AC drive. Consult the drive’s documentation or seek expert assistance to guarantee appropriate setting and optimisation of the regenerative braking and dynamic braking functions.

Asteam Techno Solutions Pvt ltd has technical expert team with almost more than 10 years of experience in industrial automation field who can assist you as well as suggest you best possible solutions as per your need.